Variable displacement motors

Power hydraulics

- Connectors

- Hydraulic tubes

- Clamps

- Hose fittings and ferrules

- Hydraulic hoses and accessories

- Measuring technology

- Ball valves

- Hydraulic quick couplings

- Hydraulic pumps

- Hydraulic motors

- Directional control valves

- In-line valves

- Sub-plate mounted valves CETOP

- Cartrige valves and accessories

- Sublates and manifolds

- Hydraulic accumulators

- Drive technology

- Reservoirs and accessories

- Electric motors and accessories

- Filtering technology

- Heat exchangers

- HP CLEAN cleaning system for hydraulic lines

- Oil and coolant cleaning systems

Hydraulic power packs

Industrial hoses

Machines and equipment

Carwash components

- Pumps

- Motors

- Pump accessories

- Guns and nozzles

- Lances and accessories

- Rotary booms and fittings

- Hoses and hose assemblies

- Hose fittings

- Tubes, fittings and clamps

- Valves, controllers and pressure gauges

- Water treatment and accessories

- Vacuum cleaners and accessories

- Payment systems

- Additional accessories

- Automotive chemicals

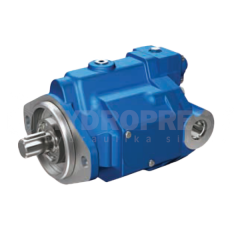

EATON closed-loop piston motors 71392 series - medium duty

Eaton closed-loop variable displacement motors 71392 series – medium duty

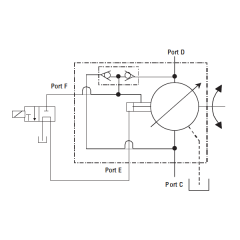

Working Principle

Axial piston motor uses a variable cam / swash plate to change the motor displacement. Shuttle valve mounted on end cover, ports high pressure oil from either side to the control piston. When the control valve is energized, ports E and F are connected and therefore contain equal pressure. The area differential (rod side vs back side of the piston) creates a force that pushes the piston to the right, taking the motor to max displacement. High side system pressure (not charge pressure) must be used to actuate the cylinder. Most of the flow from the pump goes to turn the rotating kit, leaving only a small amount of flow to go across the shuttle valve and into the cylinder. Therefore, there is no issue with too much flow going into the cylinder and having nowhere to go.

| SPECIFICATION | MODEL 71302/71392 |

|---|---|

| Maximum Displacement | 40.6 to 21.0 cm3/r [2.48 to 1.28 in3/r] |

| Maximum Rated Speed | 3600 RPM at 17° Conrol Angle |

| 4500 RPM at 9° Control Angle | |

| Nominal Pressure Rating* | 350 bar [5076 lbf/in2] |

| Peak Pressure Rating** | 370 bar [5400 lbf/in2] |

| Input Flow at Rated Speed | 175.71 l/min [38.65 GPM] at and Pressure 17° Control Angle |

| Output Power at Rated Speed | 85.30 kW [114.50 hp] at and Pressure 17° Control Angle |

| Output Torque at Rated Speed | 226.27 N•m [2004.54 lbf•in] at and Pressure 17° Control Angle |

| Continuous Allowable Case Pressure | 1.7 bar [25 lbf/in2] |

| Continuous Inlet Temperature | 107°C [225°F] |

| Weight/Single Motor (approximate) | 9.5 kg [21 lbs] |

*Nominal Pressure: Max delta system pressure at which component fatigue does not occur

(motor life estimated by bearing life).

**Peak Pressure: Max operation pressure which is permissible for a short duration of time (t < 1 sec).

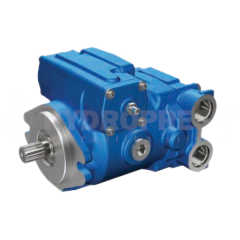

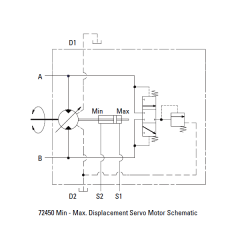

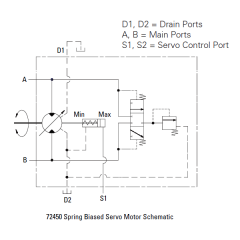

EATON closed-loop piston motors 72450 series - medium duty

Features

• SAE B- B, 2 Bolt Mount, Cradle Swashplate

• Bi-directional rotation

• Auxiliary through-drive shaft available for brake mounts

• Standard SAE splined shafts, Optional taper shafts

• Same Side ports

• System pressure guage ports

• Optional shuttle valve available

| SPECIFICATION | MODEL 72450 | MODEL 72450 |

|---|---|---|

| Maximum Displacement | 40.6 cm3/r [2.48 in3/r] | 49 cm3/r [3.00 in3/r] |

| Maximum Rated Speed | 4500 RPM at minimum stroke angle | 4500 RPM at minimum stroke angle |

| 3600 RPM at maximum stroke angle | 3600 RPM at maximum stroke angle | |

| Nominal Pressure Rating* | 350 bar [5076 lbf/in2] | 280 bar [4061 lbf/in2] |

| Peak Pressure Rating** | 372 bar [5395 lbf/in2] | 310 bar [4496 lbf/in2] |

| Input Flow at Rated Speed and Pressure | 175.71 l/min [38.65 GPM] | 212.53 l/min [46.75 GPM] |

| Output Power at Rated Speed and Pressure | 85.30 kW [114.50 hp] | 82.36 kW [110.81 hp] |

| Output Torque at Rated Speed and Pressure | 226.27 N•m [2004.54 lbf•in] at 17° Control Angle | 218.47 N•m [1940 lbf•in] at 17° Control Angle |

| Continuous Allowable Case Pressure | 1.7 bar [25 lbf-in2] | 1.7 bar [25 lbf-in2] |

| Continuous Inlet Temperature | 107° C [225° F] | 107° C [225° F] |

*Nominal Pressure: Max delta system pressure at which component fatigue does not occur (motor life estimated by bearing life).

**Peak Pressure: Max operation pressure which is permissible for a short duration of time (t < 1 sec).

DuraForce motors HMV, HMR series

Eaton's DuraForce family of variable axial piston motors features the HMV and HMR Series - both delivering smooth repeatable torque delivery, high efficiency through the operating range and durability to handle extreme duty cycles. Both product series can be purchased in sizes from 55cc to 280cc and are well packaged to fit in tight spaces.

Addresses these engineering challenges:

Sensitive applications can require a high starting torque efficiency in order to maintain smooth, repeatable torque delivery at low speed conditions.

Smooth low-speed operation

High starting torque

Wide torque / speed conversion range

Highly dynamic response characteristics

Compact design

High power density

High reliability

Long service life

Simplified drive line

Features and Benefits:

- Modular design allows promote greater flexibility for possible applications

- Easily configurable, interchangeable controls optimize system efficiency

Technical Information

HMV Series

- Stepless or two position control

- Electric or hydraulic control

- Override pressure control possible

- Brake pressure shut off possible

- Can be set to 0 cm³/rev

- Double motor available

- Displacement ranges: 35 cc to 280 cc (2.14 cu in to 17.1 cu in)

- Pressures range: up to 420 bar (6,100 psi)

HMR Series

- Optionally with purge valve for circuit and case flushing in closed loop circuit

- System pressure regulation, no external control lines required

- Brake pressure shut off for closed loop circuit

- Counterbalance (brake) valve CBV optional

- Displacement ranges: 35 cc to 280 cc (2.14 cu in to 17.1 cu in)

- Pressures range: up to 420 bar (6,100 psi)

Motors BAV7 series

The new BAV7 series bent axis motors are designed for operation in both open and closed circuit. Incorporating the lens shaped proven design valve plate, high quality components and manufacturing techniques allow the BAV7 series motors to operate up at 430 bar (6235 psi) continuous and 480 bar (6960 psi) peak pressures. Fully laboratory tested and field proven, these motors provide maximum efficiency and long life even in the most demanding conditions. Heavy duty bearings permit high radial and axial loads. The versatile design includes a variety of control and mounting options that will adapt the BAV7 series motors to any industrial or mobile application. A full range of options are available to tailor these units to your application needs. To optimize vehicle operating characteristics, an array of control options are available on variable displacement models; automatic, operator selectable, hydraulic pressure response and proportional, electric proportional, manual.

Typical Applications:

• Earth moving machines and construction equipment

• Agricultural and forestry vehicles

• Marine and off-shore equipment

• Industrial conveying, mixing & other stationary in-plant uses

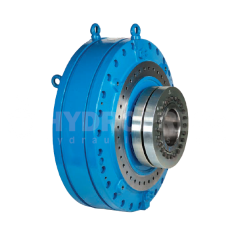

Eaton Hydre-MAC low-speed radial motors

Hydre-MAC™ Radial piston motor Direct drive variable speed machines benefit dramatically from Eaton’s new radial piston hydraulic motor. Class leading torque density decreases machine structural element costs, and reduces machine footprint. Superior mechanical efficiency further reduces energy consumption across a 2000:1 speed ratio while delivering full torque to the machine shaft. Over 90% stall torque efficiency allows the designer to avoid over-sizing the motor, and lowers overall maximum pressure requirements of the system. The low inertia design features enable instant stopping and reversing for highly dynamic applications and prevents torque spikes which could damage the machine elements and bearings. Shaft mounted and torque arm restrained features lowers coupling and mounting costs associated with extremely high torque applications. Multiple port configurations and locations offer the machine designer myriad solutions for the ultimate in flexibility. Integral multi-disc brake, torque arm kits and speed encoder options further expand the possibilities enabling the machine designer constraint free solutions.

Features and benefits:

• High Efficiency lowers operating costs

• Replaceable wear surfaces lowers maintenance costs by extending maintenance intervals

• Very low pressure drop delivers more output torque

• Symmetrical design reduces uneven loading to increase operating life

Applications:

- Pulp and paper

- Pulp washers

- Digesters

- De-barkers

- Conveyors

Mining:

- Bucket wheel reclaimers

- Apron feeders

- Breakers

Recycling:

- Shredders

Marine:

- Cutter wheel dredges

- Winches