Temperature sensors

Power hydraulics

- Connectors

- Hydraulic tubes

- Clamps

- Hose fittings and ferrules

- Hydraulic hoses and accessories

- Measuring technology

- Ball valves

- Hydraulic quick couplings

- Hydraulic pumps

- Hydraulic motors

- Directional control valves

- In-line valves

- Sub-plate mounted valves CETOP

- Cartrige valves and accessories

- Sublates and manifolds

- Hydraulic accumulators

- Drive technology

- Reservoirs and accessories

- Electric motors and accessories

- Filtering technology

- Heat exchangers

- HP CLEAN cleaning system for hydraulic lines

- Oil and coolant cleaning systems

Hydraulic power packs

Industrial hoses

Machines and equipment

Carwash components

- Pumps

- Motors

- Pump accessories

- Guns and nozzles

- Lances and accessories

- Rotary booms and fittings

- Hoses and hose assemblies

- Hose fittings

- Tubes, fittings and clamps

- Valves, controllers and pressure gauges

- Water treatment and accessories

- Vacuum cleaners and accessories

- Payment systems

- Additional accessories

- Automotive chemicals

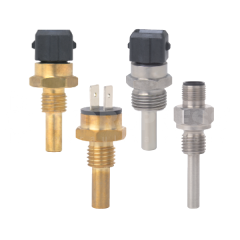

Screw-in thermometers with TF35 plug

Measuring element, tolerance

WIKA uses the following standard materials in the TF35 series:

- NTC, R25 = 2.5 kΩ ±5 %

- NTC, R25 = 10 kΩ ±5 %

- Pt100, class B acc. to DIN EN 60 751

- Pt1000, class B acc. to DIN EN 60 751

- Ni1000, DIN 43 760

- KTY10-6

- KTY10-6

- KTY81-210

Platinum elements offer the advantage of meeting international standards (IEC 751 / DIN EN 60751).

Nickel elements are also standardised, but not internationally.

Due to specific material and manufacturing criteria, the standardisation of semiconductor components (e.g. NTCs and KTY) is not possible, which is why a possibility of their replacement is limited.

Other benefits of platinum elements include both improved long-term stability and better behaviour affected by temperature cycles, a wider temperature range and high accuracy and linearity.

High accuracy and linearity are also possible with NTCs, but only in a limited temperature range.

Application:

- moving hydraulics

- mechanical engineering

- compressors

- automotive industry

- refrigeration, heating, air conditioning and ventilation technologies

Special features:

- measuring ranges -50 ... +300 °C

- high vibration resistance

- compact design

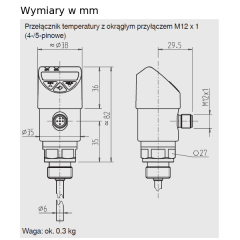

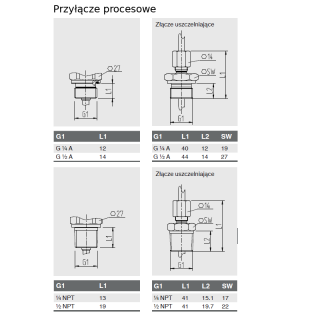

Electronic level switch with TSD-30 display

The robust LED display has been designed using 9 mm high characters (the largest possible) and with a slight incline in order to make reading the temperature as easy as possible from a long distance. A 14-segment display has been used for good legibility of text.

The 3-key operation makes simple, intuitive menu navigation possible, with no need for additional assistance. The menu navigation is designed in accordance with the latest VDMA standard. The VDMA standard for fluid sensors (24574-4, part 4 l level switches) has the aim of considerably simplifying the use of level switches by standardising menu navigation and display. The control buttons are designed as large as possible and are ergonomically arranged to ensure quick and easy setting. Operation without additional assistance is easier thanks to the tactile feedback.

The installation of the model LSD-30 level switch can be flexibly adapted to the individual mounting situation. Due to the almost unlimited rotation of the display and case by more than 300°, the display can be adjusted independently of the electrical connection. The display can thus always be aligned to face the operator, and the M12 x 1 connection positioned to suit the desired cable routing.

Application:

- machinery

- hydraulic units

- tank monitoring

- mechanical engineering

Special features:

- easily-readable, robust display

- intuitive and fast programming

- easy and flexible mounting configurations