VGMP/VGMR series orbit motors

Power hydraulics

- Connectors

- Hydraulic tubes

- Clamps

- Hose fittings and ferrules

- Hydraulic hoses and accessories

- Measuring technology

- Ball valves

- Hydraulic quick couplings

- Hydraulic pumps

- Hydraulic motors

- Directional control valves

- In-line valves

- Sub-plate mounted valves CETOP

- Cartrige valves and accessories

- Sublates and manifolds

- Hydraulic accumulators

- Drive technology

- Reservoirs and accessories

- Electric motors and accessories

- Filtering technology

- Heat exchangers

- HP CLEAN cleaning system for hydraulic lines

- Oil and coolant cleaning systems

Hydraulic power packs

Industrial hoses

Machines and equipment

Carwash components

- Pumps

- Motors

- Pump accessories

- Guns and nozzles

- Lances and accessories

- Rotary booms and fittings

- Hoses and hose assemblies

- Hose fittings

- Tubes, fittings and clamps

- Valves, controllers and pressure gauges

- Water treatment and accessories

- Vacuum cleaners and accessories

- Payment systems

- Additional accessories

- Automotive chemicals

VGMP/VGMR series orbit motors

The VGMR/VGMP series motors are characterised by:

- compact design and small footprint

- geroler-type design, with internal gear motor with rollers on the rotor perimeter and timing on the shaft

- high starting torque

- constant torque over a wide rotational speed range

- versatile application

Some applications of VGMR/VGMP series motors include:

- warehousing equipment, conveyors, forklift trucks

- agricultural machines (spreaders, harvesters, seed drills, etc.)

- street and road maintenance machines (sweepers, sand spreaders, etc.)

- construction machines (excavators, loaders, etc.)

- machine tools, conveyors, belt conveyors

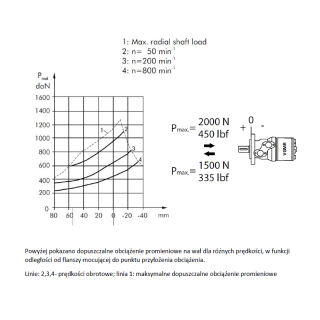

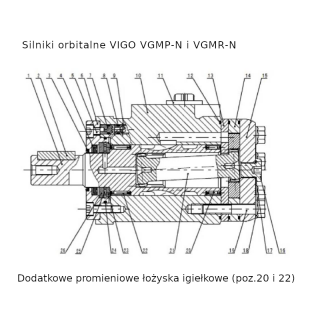

VGMP-N and VGMR-N series orbit motors

The main technical parameters of the VGMP-N and VGMR-N motors are the same as standard VGMP and VGMR motors. The difference between these options is the addition of radial needle bearings.

The motor shaft, strengthened in this way, can transmit higher radial forces (applied at a right angle to the shaft). It is recommended to use it where the motor is subjected to variable operating characteristics, frequent starts and stops, excessive shaft vibrations, etc. - where a standard VGMR motor model does not meet the requirements.